Welcome to an enlightening exploration of the revolutionary synergy between robotics, automation, and artificial intelligent in the manufacturing sector. In this post, we’ll delve into how the seamless integration of these cutting-edge technologies is reshaping the way products are produced, enhancing efficiency, precision, and adaptability.

As the manufacturing landscape undergoes a transformative journey, join us in uncovering the multifaceted impact of robotic automation and Artificial Intelligent on production processes, quality control, and the overall industry landscape.

The Power of Robotic Automation and Artificial Intelligent

Robotic automation, coupled with artificial intelligence, signifies a paradigm shift in manufacturing. Robots equipped with AI capabilities can perform tasks that require cognitive skills, pattern recognition, and decision-making.

This fusion amplifies the potential for enhanced productivity, reduced human error, manufacturing automation benefits, AI-driven robotics impact, smart manufacturing revolution and adaptive problem-solving. The convergence of robotic automation and AI opens the doors to a new era of manufacturing, characterized by efficiency, precision, and innovation.

Redefining Production Processes by Robotic Automation and Artificial Intelligent

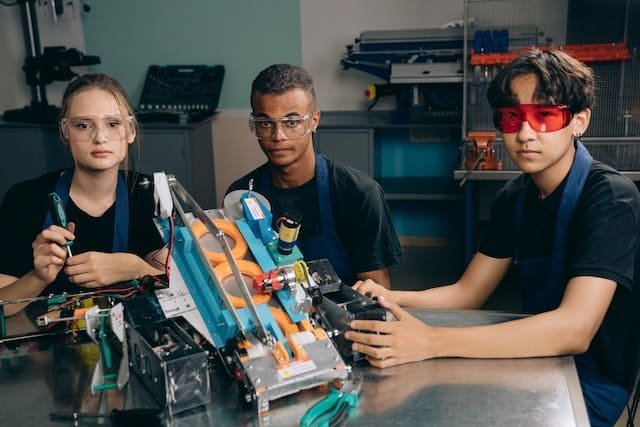

Case Study 1: Collaborative Robotic Assembly AI-driven robots collaborate with human workers in intricate assembly tasks. These robots analyze parts, anticipate assembly steps, and adjust their actions based on real-time feedback. This synergy optimizes the production line, ensuring faster output without compromising precision like Metaverse.

Case Study 2: Adaptive Manufacturing Lines AI-powered manufacturing lines dynamically adapt to changes in product demand, ensuring optimal resource allocation. Robots analyze data from various sources, such as customer orders and supply chain updates, to adjust production rates, materials, and processes accordingly.

Enhancing Quality Control

Case Study 1: Visual Inspection with AI Robotic systems equipped with AI-enhanced vision analyze product surfaces for defects, imperfections, or inconsistencies. AI algorithms identify deviations from quality standards, ensuring that only flawless products proceed down the production line.

Case Study 2: Predictive Maintenance for Equipment AI-driven analytics monitor machinery health in real-time, predicting maintenance needs before breakdowns occur.

This proactive approach minimizes downtime, optimizes equipment lifespan, AI-powered quality control, predictive maintenance advantages, smart manufacturing efficiency and maintains consistent production. AI-driven robotics redefine manufacturing quality control and equipment maintenance, resulting in higher product standards and operational efficiency.

A Sustainable Manufacturing Future

The integration of robotic automation and AI aligns with sustainability goals. Optimized production processes reduce resource waste, energy consumption, and emissions. AI-enabled predictive analytics further enhance energy efficiency and minimize environmental impact.

Empowering the Workforce

Contrary to the fear of job displacement, robotic automation and AI empower the manufacturing workforce. Robots take over repetitive and strenuous tasks, allowing human workers to focus on higher-value activities such as creativity, problem-solving, and innovation.

Realizing Industry 4.0

The synergy of robotic automation and AI is a cornerstone of Industry 4.0, the fourth industrial revolution. Smart factories equipped with interconnected devices, data analytics, and autonomous systems drive efficiency, agility, and responsiveness in manufacturing.

Embracing a Transformative Future

As manufacturing evolves, the amalgamation of robotic automation and AI holds the promise of a transformative future. The manufacturing landscape will witness accelerated innovation, heightened precision, and expanded capabilities, ultimately shaping a new era of possibilities.

Conclusion

In conclusion, the marriage of robotic automation and AI is revolutionising manufacturing, forging a path toward unparalleled efficiency, quality, and sustainability. From collaborative assembly lines to predictive maintenance, this dynamic synergy redefines how products are made and paves the way for Industry 4.0.

As the manufacturing sector continues to embrace these advancements, we’re entering an era where human ingenuity and technological prowess converge to shape a brighter, more adaptive future for manufacturing.

1 thought on “Revolutionising Manufacturing with Robotic Automation and Artificial Intelligent”

Comments are closed.